Typically, baseball caps are still often made of solid-color wool. Some caps not used expressly for baseball, but are of the baseball cap style and have company or other logos on them are of cotton or cotton-synthetic combinations. The visors of these caps always include some kind of stiffening. Sometimes this stiffening is called “buckram”, other times it is a plastic insert (the material depends on the company).

Some caps are stiffened in center front to accommodate the embroidered logo and this may be accomplished by sewing various kinds of stiffeners in the two front panels. Sweatbands may be cotton or even thin leather depending on the company or product.

Because the design of baseball caps has varied little, the design often changes only in the color of fabric used for the hat and the logo on the center front of the hat. Some companies have tinkered with the basic baseball cap design in order to get a better-fitting cap on the head.

Other companies may experiment with the insert into the visor in order to render the visor flexible but sturdy. Elaborately embroidered logos, some of which include over 30,000 stitches in order to produce the logo, are carefully designed with the aid of a computer in order to perfectly and consistently sew that logo onto the front of the caps.

Interestingly, a few companies actually reproduce old-style baseball caps that were popular over 100 years ago. These companies cannot take apart the old caps in order to draft a prototype pattern but must work from whole pieces that are visually examined and measured in order to make these patterns.

At Proud To Buy American®, and down to the finest of details, we have gone the extra mile to ensure that we hold true to our core company values. We also fully support the American manufacturing industry and the jobs market. This is our corporate mission. Every product, element, and label offers supportive documentation that it truly is made in the USA.

PTBA baseball caps are made with the utmost care and quality including:

• Pure Cotton Twill: An innovative, 6-panel top quality fabric for a durable yet classic look.

• Adjustable Closures: 3 options including embroidered leather, or brass “Tri-Glide” or Velcro for a one-size fits all.

• Premium Sweatband: Cool and comfortable while offering handmade workmanship.

• American Flag with Logo: An astonishing 22,000+ stitches in the logo alone! Precision embroidering with the PTBA® design in red, white and blue.

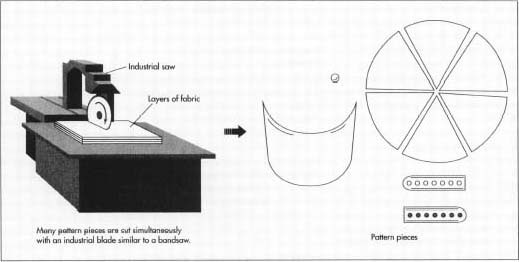

The Proud To Buy American® manufacturing process is tedious. We provide some of the highest quality control standards in the industry. A remarkable number of these steps are accomplished by hand using a sewing machine. Thus, the sewing machine operative can and does notice any quality inconsistencies in the product. Of course, all raw materials are held to the standards the company requires and for Proud To Buy American, every material, fabric and sourcing is 100% Made in the USA.